Chromic Anodize: The Underrated Hero of Durable Finishes

Chromic Anodize: The Underrated Hero of Durable Finishes

Have you ever wondered how certain metal parts manage to maintain their pristine appearance and resist corrosion, even in harsh environments? The answer might lie in a process called chromic anodize. Let’s delve into this fascinating technique and uncover its benefits.

What is Chromic Anodize?

Chromic anodize, also known as Type I anodizing or chromic acid anodizing, is an electrochemical process that creates a protective oxide layer on the surface of aluminum. This layer enhances the metal’s corrosion resistance, wear resistance, and aesthetic appeal. It’s particularly valued in industries like aerospace, defense, and automotive where durability and reliability are paramount.

The Chromic Anodizing Process

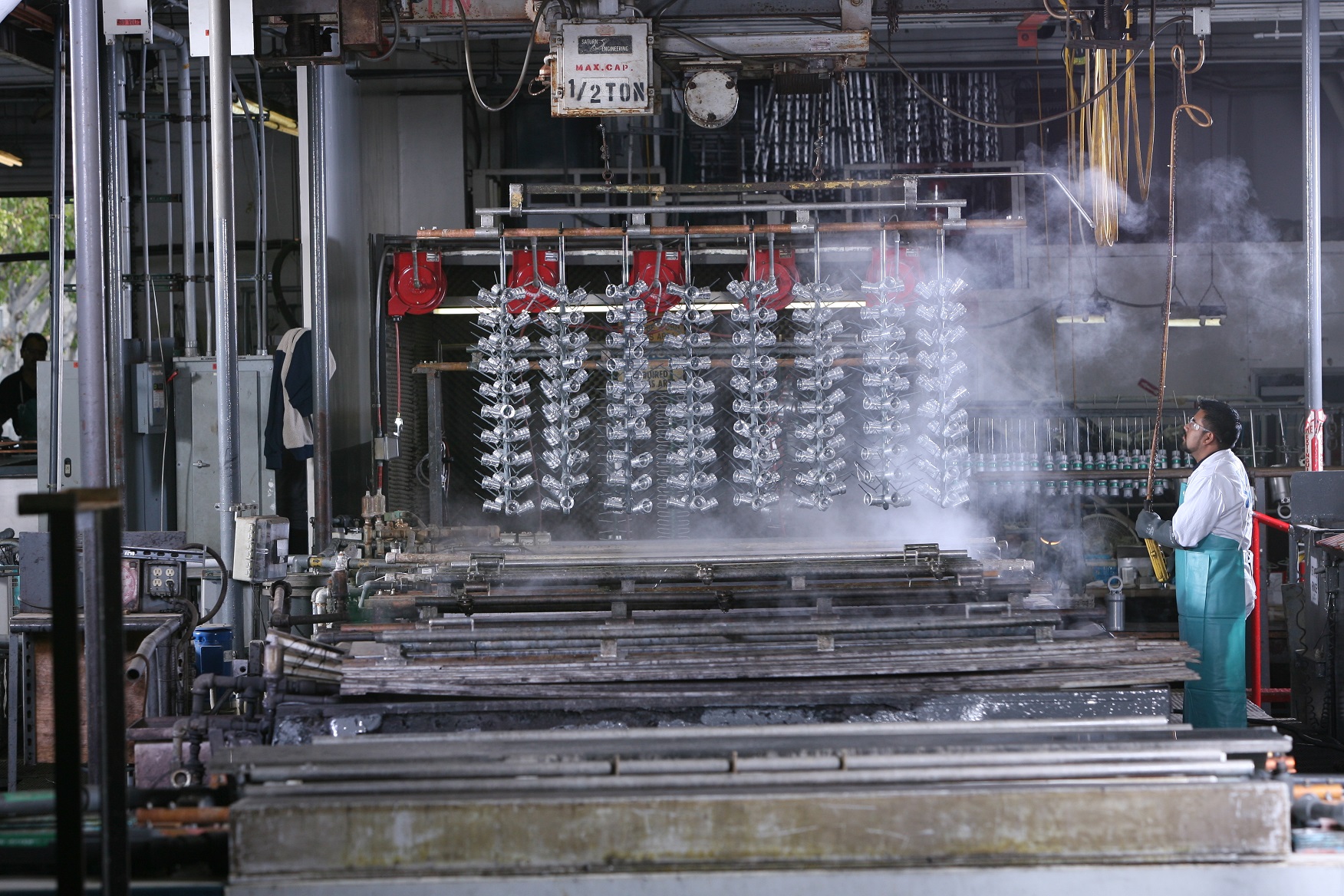

The process involves immersing the aluminum part in a chromic acid bath and passing an electric current through it. This causes oxygen ions to react with the aluminum, forming a thin, dense oxide layer. The thickness of this layer can be controlled, typically ranging from 0.00005 to 0.001 inches.

Advantages of Chromic Anodizing

- Exceptional Corrosion Resistance: The chromic oxide layer acts as a barrier, protecting the underlying aluminum from moisture, salt, and other corrosive elements.

- Superior Wear Resistance: The hard, dense oxide layer also improves the metal’s resistance to abrasion and scratching.

- Excellent Adhesion: The chromic oxide layer provides a good base for paints, primers, and adhesives, ensuring a long-lasting finish.

- Electrical Insulation: The oxide layer is an electrical insulator, making it suitable for applications where electrical conductivity needs to be controlled.

- Non-Toxic: Unlike some other anodizing processes, chromic anodizing does not involve the use of hazardous chemicals, making it a more environmentally friendly option.

Chromic Anodize vs. Other Types of Anodizing

While chromic anodize offers several advantages, it’s important to understand how it compares to other anodizing processes, such as sulfuric anodizing (Type II).

- Color: Chromic anodize typically produces a greenish-gold or iridescent finish, while sulfuric anodize can be dyed in a wider range of colors.

- Thickness: Chromic anodize generally produces a thinner oxide layer than sulfuric anodize.

- Applications: Chromic anodize is often preferred for applications requiring high corrosion resistance and electrical insulation, while sulfuric anodize is more common for decorative purposes and applications where a thicker oxide layer is desired.

Finding Chromic Anodizing Services

If you’re looking for chromic anodizing services, you can search online for “chromic anodize near me” or “chromic anodizing aluminum” to find local providers. Make sure to choose a reputable company with experience in chromic anodizing and the ability to meet your specific requirements.

Conclusion

Chromic anodize is a valuable process that enhances the durability, performance, and aesthetic appeal of aluminum parts. Its exceptional corrosion resistance, wear resistance, and other benefits make it an ideal choice for demanding applications. If you’re looking for a reliable and long-lasting finish for your aluminum components, consider chromic anodize.

Embee Services: