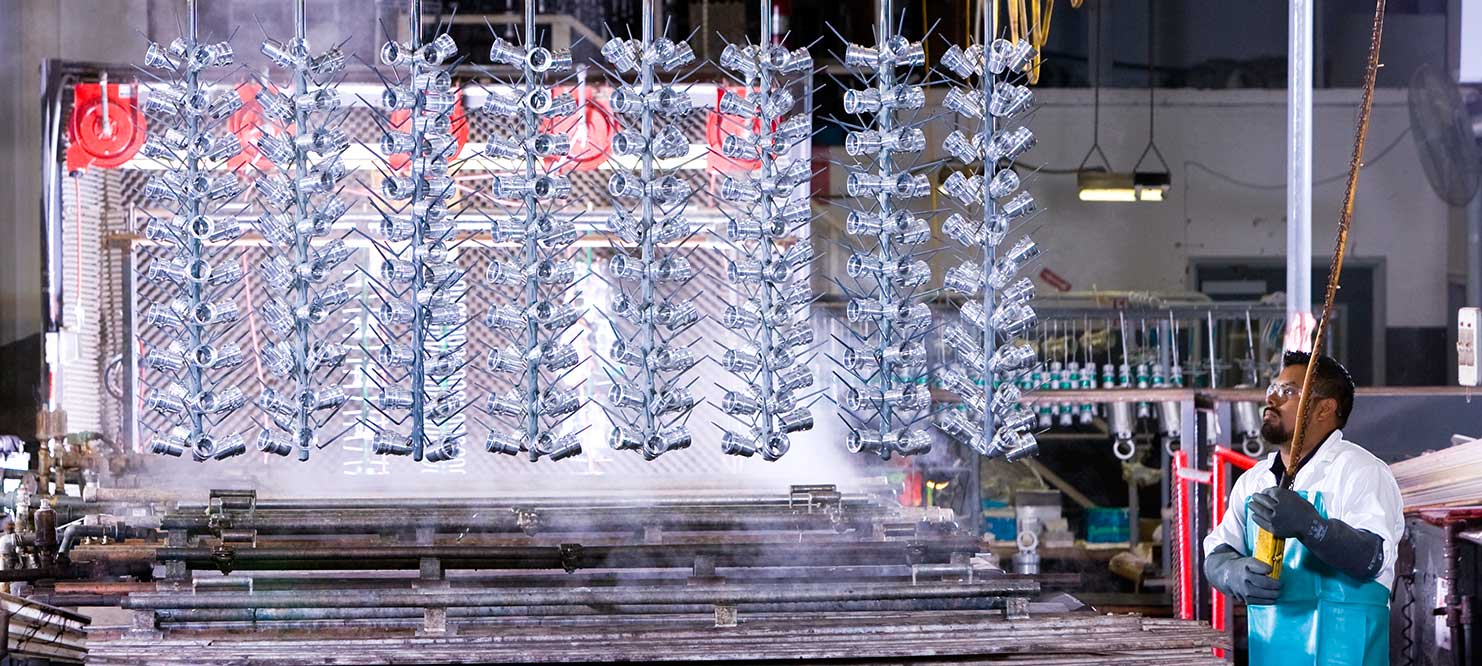

Plating Overview

Embee offers complete, start-to-finish production capabilities designed to meet virtually any metal-finishing need. Our 124,000 sq. ft, 10-building campus provides the ultimate in one-stop convenience - a level unattainable with smaller shops or multiple vendors. Hallmark benefits of Embee's operation include unsurpassed quality, shorter lead times, lower fuel and transportation costs and simplified accounting.

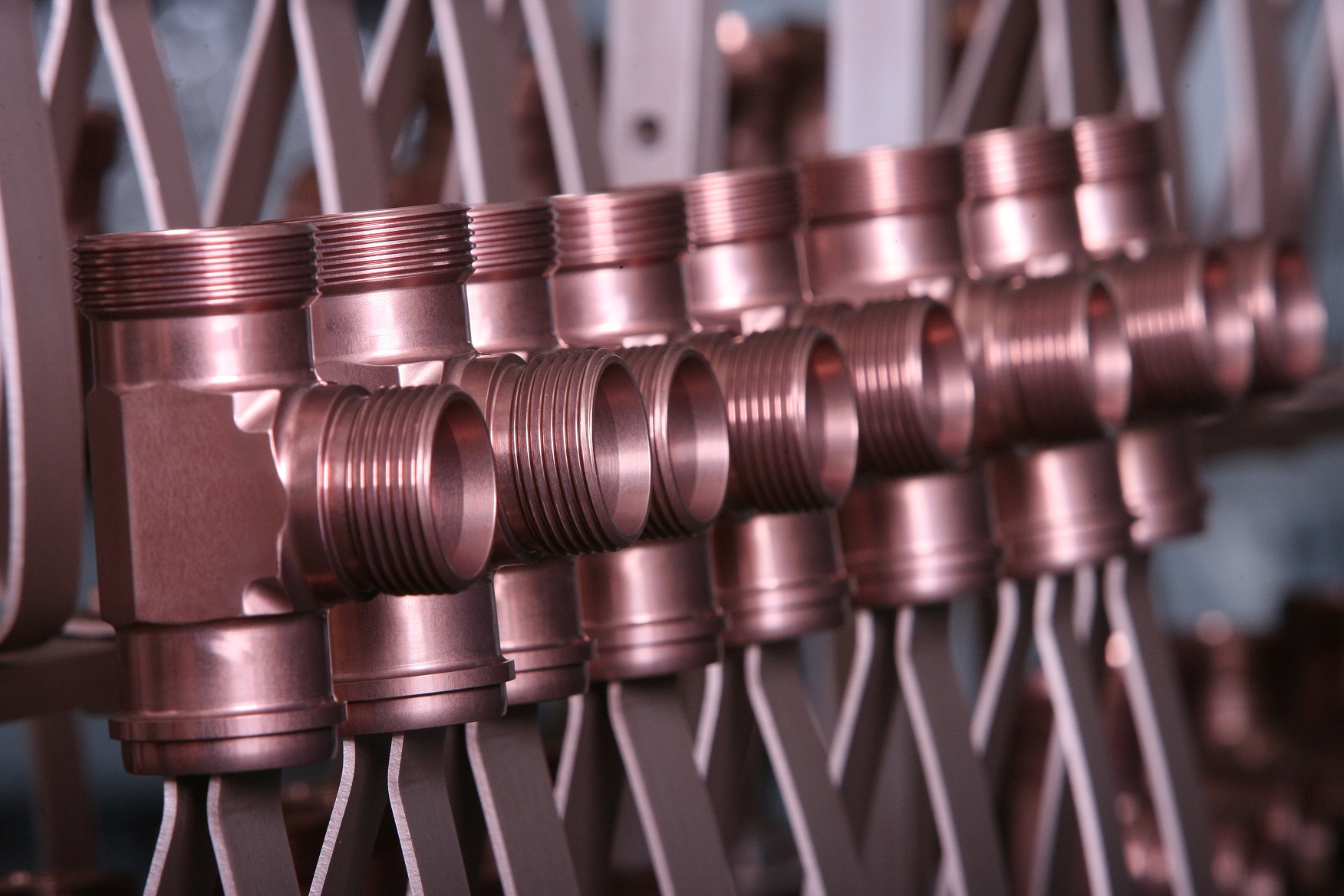

Conversion & Pre-Treatment

To promote adhesion and prevent corrosion of the base metal, we provide a variety of high-quality pre-treatments for steel and aluminum to do the job right. Embee provides a variety of conversion and pretreatment processes for both steel and aluminum that improve appearance or corrosion resistance and promote adhesion of organic coatings.

Embee Grind

The vast array of part configurations on components require the chrome or HVOF surfaces to be ground/polished/honed/deburred after plating to achieve the desired surface finish. We perform all these operations at our facility ensuring your finish is flawless. Our 8000 square foot grind shop operates twelve Studer CNC grinders with I.D., O.D., and Form grind capabilities. We also have four Okamoto NC OD grind machines, three centerless grinders, plus thread, surface and superfinish grinding abilities.

Vacuum Metalizing

We helped pioneer the environmentally friendly Ion Vapor Deposition (IVD) process and remain leaders in this area. Industry experts recognize IVD as a cost effective, viable alternative to wet plating. Aluminum coatings using IVD offer a versatile, high-performance, corrosion resistant coating able to meet a wide variety of requirements. Our full service department offers both rack and barrel coating services and performs ion vapor deposition (IVD) of aluminum and vacuum cadmium.

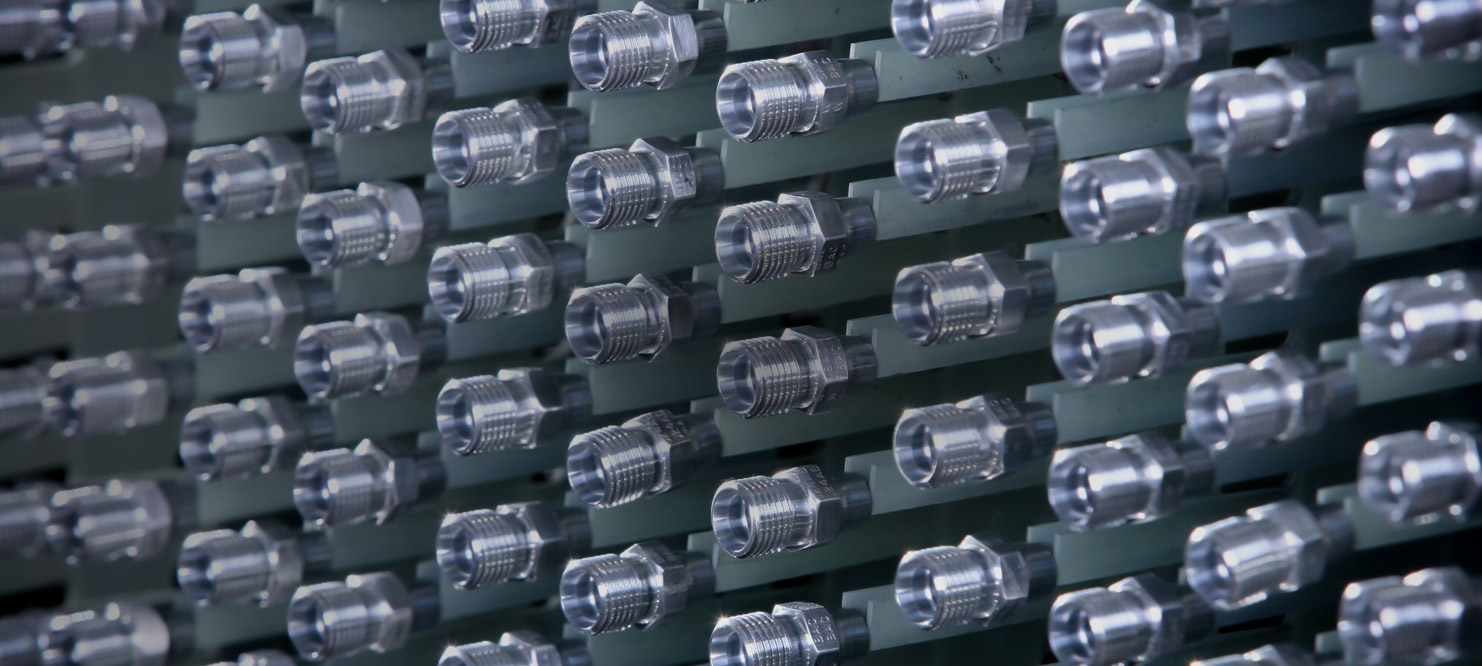

Additional Capabilities

Embee provides over 70 metal plating finishes as well as the required testing all on site. We are continually expanding and adding new processes and spec approvals to better serve our customers. Additional capabilities are Silver plating, Blast, Pickle, Etch, Stress Relieve, and Identification and a Quality team to facilitate Government Source Inspection on site.