Sulfuric Anodizing: The Unsung Hero of Durable Aluminum

Sulfuric Anodizing: The Unsung Hero of Durable Aluminum

Sulfuric Anodizing: The Unsung Hero of Durable Aluminum

Have you ever wondered how aluminum, a relatively soft metal, transforms into a powerhouse of durability and corrosion resistance? The secret lies in a fascinating process called sulfuric anodizing. Let’s delve into the world of sulfuric anodizing, exploring its process, benefits, and why it’s the go-to choice for a wide range of applications.

What is Sulfuric Anodizing?

Sulfuric anodizing, also known as Type II anodizing, is an electrochemical process that enhances the natural oxide layer on the surface of aluminum. This thickened oxide layer provides a multitude of benefits, including increased hardness, wear resistance, corrosion protection, and improved adhesion for paints and dyes.

The Sulfuric Anodize Process

The process involves immersing aluminum parts in a sulfuric acid bath and passing an electric current through the solution. This causes oxygen ions to react with the aluminum, forming a porous oxide layer on its surface. The size of these pores and the thickness of the layer can be controlled by adjusting the process parameters, such as acid concentration, temperature, and current density.

After anodizing, the parts are often sealed to close the pores in the oxide layer, further enhancing its protective properties. Sealing can be done using hot water, steam, or various chemical solutions.

Sulfuric Anodize Benefits: Why Choose It?

- Exceptional Durability: The hard anodized layer formed through sulfuric anodizing is incredibly tough and wear-resistant, making it ideal for applications that experience high levels of friction or abrasion.

- Corrosion Resistance: The thickened oxide layer acts as a barrier against corrosive elements, significantly extending the lifespan of aluminum parts in harsh environments.

- Excellent Adhesion: The porous structure of the anodized layer provides an excellent mechanical bond for paints, dyes, and adhesives, ensuring a long-lasting and vibrant finish.

- Electrical Insulation: The anodized layer is a good electrical insulator, making it suitable for applications where electrical conductivity needs to be controlled.

- Cost-Effectiveness: Sulfuric anodizing is a relatively inexpensive process compared to other types of anodizing, making it an attractive option for a wide range of industries.

Applications of Sulfuric Anodizing

The versatility of sulfuric anodizing makes it a popular choice across various industries, including:

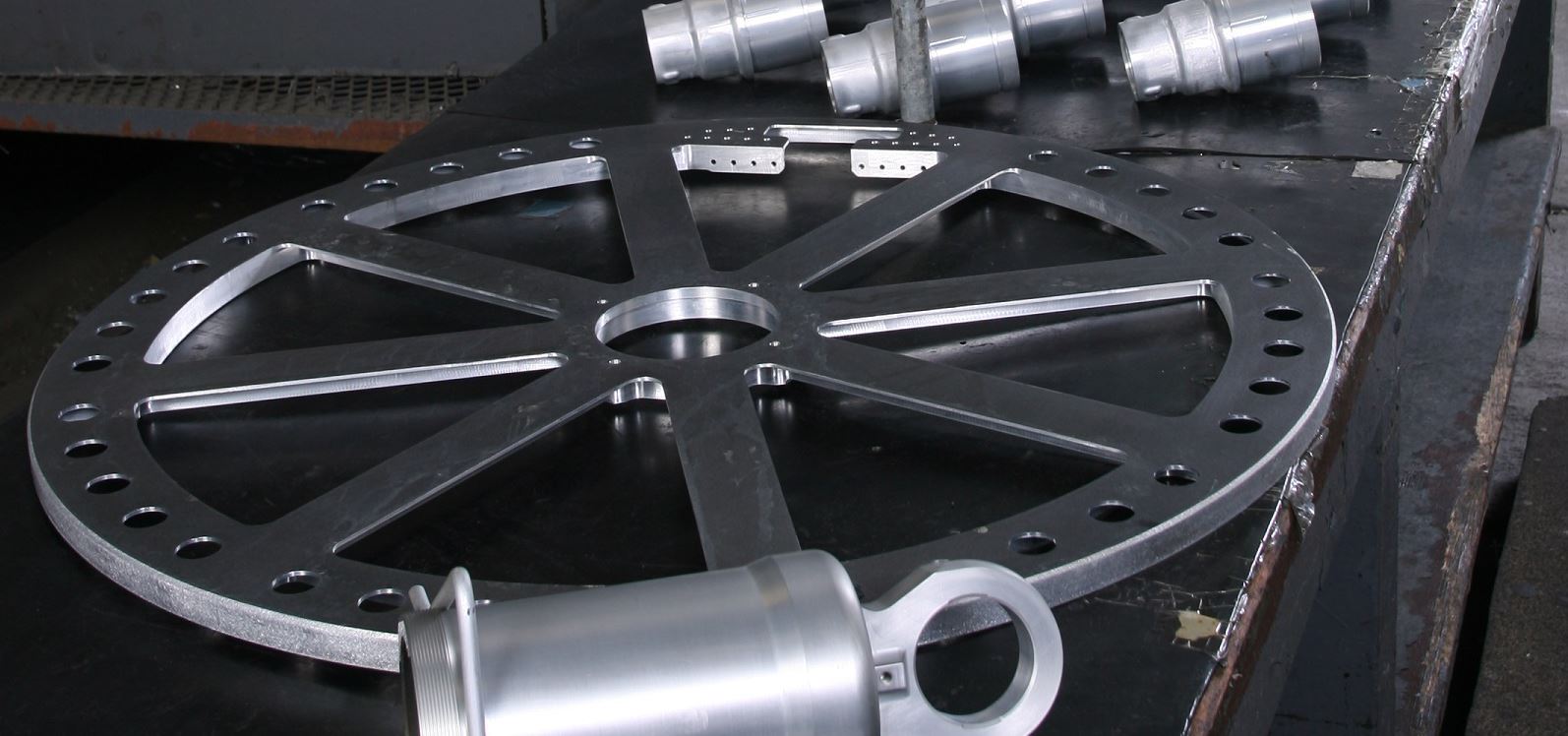

- Aerospace: Sulfuric anodizing is used to protect aircraft components from corrosion and wear, ensuring their reliability and longevity.

- Automotive: Aluminum parts in automobiles, such as engine blocks, wheels, and trim, are often anodized to enhance their durability and appearance.

- Architecture: Anodized aluminum is used extensively in building facades, windows, and doors due to its aesthetic appeal and resistance to weathering.

- Electronics: Sulfuric anodizing is employed to protect electronic components from corrosion and provide electrical insulation.

- Consumer Goods: Anodized aluminum is found in a variety of consumer products, such as cookware, sporting goods, and jewelry, due to its attractive finish and resistance to scratches and stains.

Sulfuric Anodizing vs. Hard Anodizing

While sulfuric anodizing offers excellent durability, hard anodizing takes it a step further. Hard anodizing, also known as Type III anodizing, uses a specialized electrolyte and lower temperatures to create an even thicker and harder oxide layer. This makes it the preferred choice for applications that demand extreme wear resistance, such as hydraulic cylinders, gears, and firearms components.

Embee Services

- Sulfuric Anodizing

- Hard Anodizing

- Chrome Plating Services: Find a Plater Near You

- Chemical Conversion Coatings

- Fuel Tank Coatings